Biomethane presents a unique advantage as the lowest cost, lowest complexity and fastest path to decarbonisation through the replacement of natural gas. It is a major energy source that modern industries can rely upon and solves multiple additional challenges including fugitive emissions from waste.

Often referred to as renewable natural gas, biomethane is a green alternative to conventional (fossil fuel) natural gas. It is primarily composed of methane and is produced through the anaerobic digestion or gasification of organic materials such as agricultural waste, municipal solid waste, plant material, and sewage.

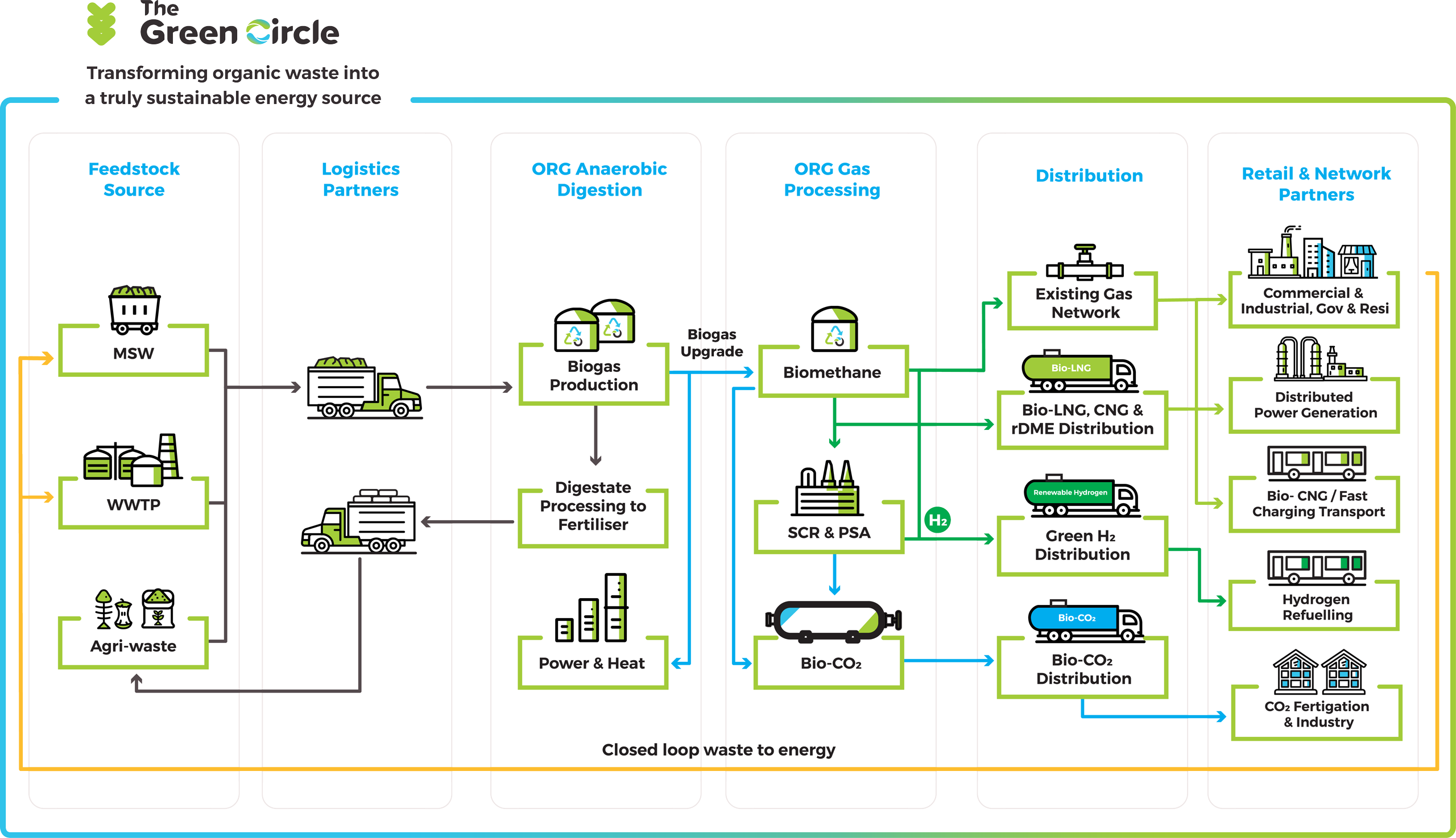

During anaerobic digestion, microorganisms break down these biodegradable materials in an oxygen-free environment, producing biogas that predominantly contains methane and carbon dioxide. This biogas can then be purified to remove the carbon dioxide, impurities, and other non-methane components, resulting in high-quality biomethane.

Biomethane can be seamlessly integrated into existing natural gas infrastructure. This makes it a direct replacement for fossil-fuel based natural gas in applications such as heating, cooking, and power generation. Switching to biomethane is beneficial for the environment as it harnesses methane, a potent greenhouse gas, from organic waste that would otherwise be released into the atmosphere.

Additionally, its production and use create a closed carbon loop, where the CO2 emitted during its combustion originates from plants that absorb the same CO2 during their growth. This results in net-zero carbon emissions as compared to the ongoing carbon-positive releases from fossil-fuel-derived natural gas. Biomethane is a great option to use alongside wind and solar energy to reduce emissions in hard-to-abate sectors such as industrial heat, to ensure that we meet our sustainability targets.

Biomethane production through anaerobic digestion plays a crucial role in the circular economy by converting organic waste into renewable energy and nutrient-rich fertilisers, closing the loop on waste and resources.

Whilst hydrogen continues to draw attention as a renewable gas solution with large-scale potential for decarbonisation, there are multiple technical hurdles which serve as barriers to its widespread adoption.

The most prevalent processes for industrial production of hydrogen gas can be categorised into two types; brown hydrogen, derived from coal or lignite gasification and grey hydrogen, produced through steam methane reformation with natural gas as a feedstock. While offering low cost of hydrogen production, neither of these methods are climate-friendly, as they both emit large amounts of carbon dioxide into the atmosphere.

Blue hydrogen, where the CO2 emissions from steam reforming are captured and sequestered underground, has been mooted as a clean way of using fossil fuels to produce hydrogen. However, blue hydrogen remains controversial as the technology has not been demonstrated reliably at scale and is very energy-intensive.

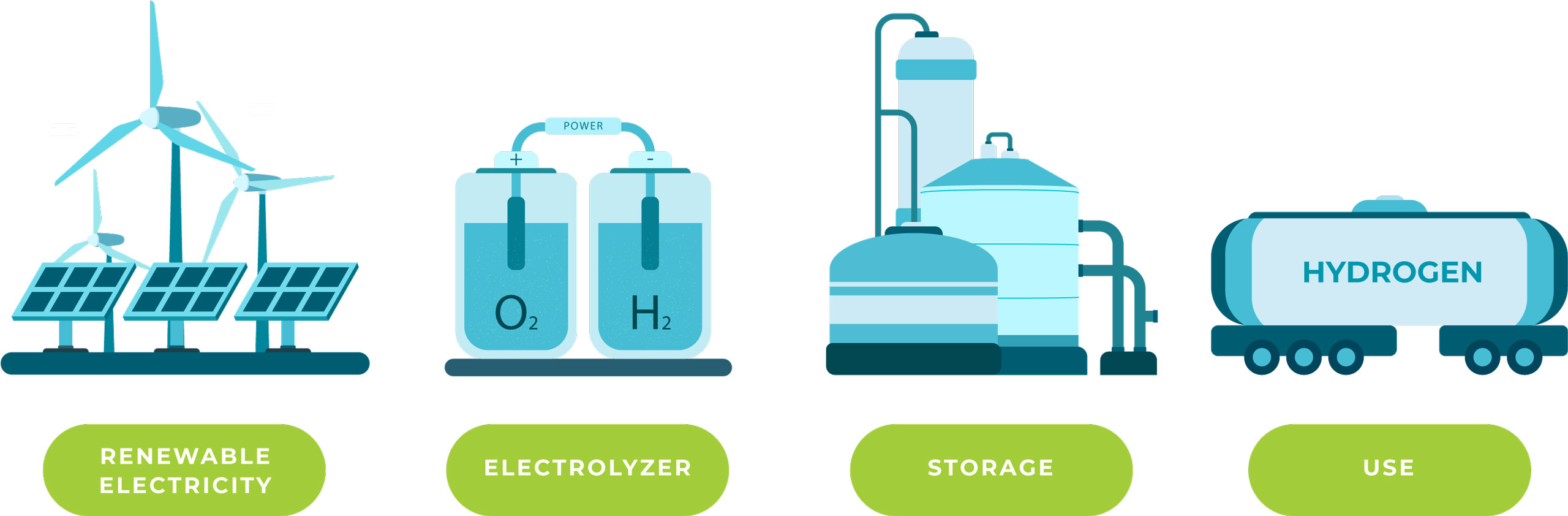

Green hydrogen shows great potential for nearly eliminating emissions by utilising renewable energy, often available at non-optimal times, for water electrolysis. However widespread adoption faces challenges, including a shortage of large-scale electrolysers and the cost of procuring a reliable supply of renewable electricity. Renewable hydrogen can also be produced as bio-hydrogen through processes such as pyrolysis of biomass residues.

One of the primary hurdles to green hydrogen adoption is distribution to its end-users. Transporting this highly flammable gas is complex, as it requires high-pressure storage and can compromise the integrity of steel pipes and welds. This necessitates dedicated pipelines or energy-intensive processes such as pressurisation and liquefaction for bulk transport. These requirements further diminish green hydrogen’s overall efficiency.

To make a business case for green hydrogen, substantial quantities of inexpensive renewable electricity are required. This is due in part to significant energy losses during the electrolysis process, which typically operates with efficiencies ranging from 60% to 80%. This efficiency challenge is compounded by applications often using green hydrogen for fuel cells, incurring additional losses.

Renewable Dimethyl Ether (rDME) is a safe, eco-friendly and sustainable fuel that may form part of the net zero energy mix. Applications for the use of rDME are found in the transportation, residential and industrial heating and culinary sectors. DME is a molecule that may be obtained from a diverse array of renewable feedstocks. Chemically akin to propane and butane, it exists in gaseous form at standard temperature and pressure conditions. Like Liquified Petroleum Gas (LPG), it can be conveniently transported in liquid form within pressurized cylinders and tanks. The utilization of rDME has the potential to curtail greenhouse gas emissions by as much as 85% when compared to conventional diesel and heating oil. This substitution also leads to marked improvements in air quality.